UX Case Studies

Carpenter Technologies

Summary of Company

Carpenter is a steel mill located in Latrobe, PA. Currently, the machines are not monitored efficiently so they tend to break often. Life and safety code requires annual inspections of equipment at the facility.

Their Current Pain Points

- Inefficient preventative maintenance system

- Double entry problem

- Handwritten illegibility

My roles for this project

- Design Research

- Visual Design

- User Testing

User Experience in Current System

First, we met with the head of maintenance at Carpenter Latrobe to discuss their current workflow.

The current system works as follows:

1. Locate equipment

2. Fill out a paper form

3. Sign off on a paper that is attached to the equipment

4. Enter form into database, located on computer in office

Some of the issues that we identified right away were inefficiencies in locating certain assets, handwritten errors, and the time spent entering data from the forms into the computer.

Through talking with different people at the facility, we were able to create personas and develop a list of user requirements.

Users and Their Needs

Tim

Maintainence Employee

Works on all types of equipment around the facility. Currently uses paper and pencil and then has to enter results into excel after his manual work is finished.

Toni

Head of Maintenance

Manages the maintenance team and oversees the purchasing for repairs and new equipment. Her main goal is to reduce the workload of her employees on redundant tasks.

David

Corporate

Sits on the board and approves corporate spending. His main goal is to be able to save money and time for his company.

Features Needed in Our Software

-

create a campus, building, and floor-plan on the map

-

place, move, delete, and view assets on a floor-plan or campus

-

define custom inspections associated to various asset types that will be set to a recurring interval

-

fill out inspections for a particular asset

-

view a list of campuses, buildings, floor-plans, and assets including details around each entity

-

create users within the system and set various permission levels

We started with posted notes on the wall in our office to making some low fidelity wireframes on marvel to allow for user testing.

After Multiple Iterations

Our initial focus for the app was on locating assets and digitizing the inspection process. We started designing an app that would allow maintenance workers to quickly locate assets and enter the data from inspections directly.

Blueprints/Floorplans

We wanted to give the manager the ability to upload floor plans for multiple facilities on one device.

We created this feature which allows the user to see all facilities that they manage, and add or delete campuses or buildings from their mobile device.

Manage and View Assets

The first challenge that users had in the current inspection process was locating specific assets for inspection.

We created a tool that allows users to mark assets on the floor plan. When all the assets are marked at once, the floor plan can appear crowded, so we created a filter feature. We also added a search function to improve usability.

Paper to Digital Inspections

We designed an inspection form based off the paper forms, which allows workers to directly enter information into the iPad.

We also created a way for users to update the inspection forms and add new types of interactions with the asset.

Asset Images and Locations

We also wanted to have a page for each asset where important information is stored.

When designing this, we had to create many iterations as there was a diverse set of assets that our users needed to map and maintain.

We started with simple fixed assets (such as fire extinguishers) and from there built out more sophisticated asset dashboards (such as furnaces).

User Dashboard

One of the things that the manager needed from the software was the ability to monitor and search employees.

We created an employee dashboard that allowed the manager to track simple information such as certifications, job title, and other relevant information.

We created different user levels, so that managers can see all dashboards as admins and other users can only see information relevant to their work.

Final Prototype

PM:

-

Translated paper inspections into digital versions with capability to take pictures and have geographical location attached to each asset

-

Along with inspections, created PM notification system to help reduce expenses from miscommunication between employees or loss of paper records

Double entry:

-

Real time inspections directly on the mobile application eliminates the process of recording on paper and then entering the information into IBM database.

-

Discussed integrating with their current database through IBMs API (or gave options of cutting cost by providing analytics of our own and just recording information on AWS or other cloud services)

Handwritten costs:

-

Eliminating handwritten mistakes when entering inspections into the database ( which leads to PM work not being done, done incorrectly etc.)

Queryable data on hand:

-

Currently exists on their database but is not mobile

-

Which is inefficient as an employee can have everything they need on hand while making repairs and even have actual images of the problem so communication is at a companies all time high

-

Additionally being able to pass off any information to anyone who has access to the device is good for contracting companies to perform work (discussed security aspects of this and went over multiple redundancies to show how company info is secure)

-

%202.jpg)

%204.jpg)

%205.jpg)

%207.jpg)

%208.jpg)

%209.jpg)

%2010_jp.jpg)

UX Case Studies

Range Resources

Summary of Company

Range Resources Corporation is a petroleum and natural gas exploration and production company organized in Delaware and headquartered in Fort Worth, Texas. It is one of the largest exploration companies operating in the Marcellus Formation.

Their Current Pain Points

- Inefficient employee Safety Systems

- Data analysis inefficiency

- Handwritten illegibility

My roles for this project

- Design Research

- Visual Design

- User Testing

User Experience in Current System

The current system works as follows:

1. Enter pad site

2. Locate equipment

3. Sign off on a paper that is attached to the equipment

4. Enter form into database, located on computer in office

Some of the issues that we identified right away were inefficiencies in locating certain assets, handwritten errors, and the safety issues of not knowing where or who is on the pad site.

Users and Their Needs

Features Needed in Our Software

-

Asset Tracking and monitoring

-

place, move, delete, and view assets on a floor-plan or campus

-

define custom inspections associated to various asset types that will be set to a recurring interval

-

fill out inspections for a particular asset

-

view a list of campuses, buildings, floor-plans, and assets including details around each entity

-

implement employee monitoring on pad site to allow for delivery to be conducted safely

We started with posted notes on the wall in our office to making some low fidelity wireframes on marvel to allow for user testing.

After Multiple Iterations

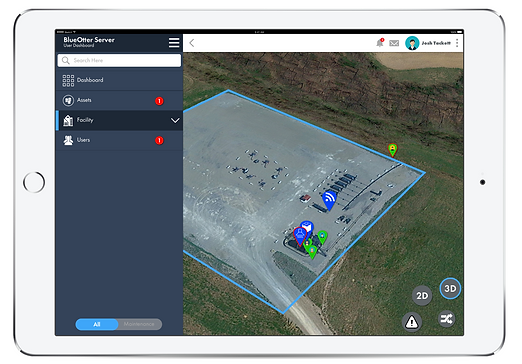

Our initial focus for the app was on locating assets and digitizing the inspection process. We started designing an app that would allow maintenance workers to quickly locate assets and enter the data from inspections directly.

Blueprints/Floorplans

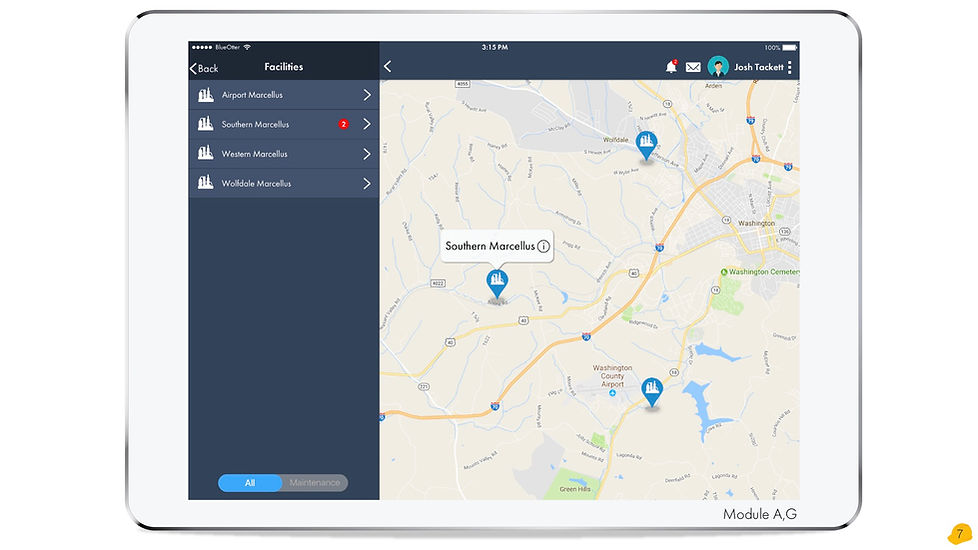

We wanted to give the manager the ability to upload floor plans for multiple facilities on one device.

We created this feature which allows the user to see all facilities that they manage, and add or delete campuses or buildings from their mobile device.

Manage and View Assets

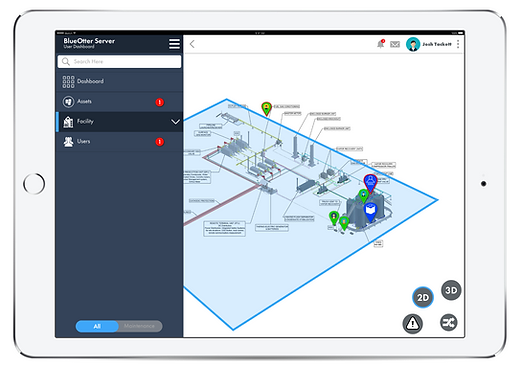

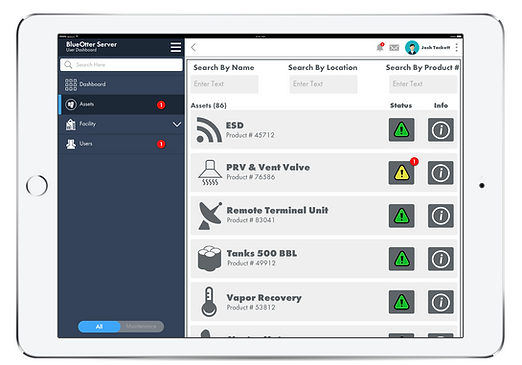

The first challenge that users had in the current inspection process was locating specific assets for inspection.

We created a tool that allows users to mark assets on the floor plan. When all the assets are marked at once, the floor plan can appear crowded, so we created a filter feature. We also added a search function to improve usability.

Paper to Digital Inspections

We designed an inspection form based off the paper forms, which allows workers to directly enter information into the iPad.

We also created a way for users to update the inspection forms and add new types of interactions with the asset.

Asset Images and Locations

We also wanted to have a page for each asset where important information is stored.

When designing this, we had to create many iterations as there was a diverse set of assets that our users needed to map and maintain.

We started with simple fixed assets (such as fire extinguishers) and from there built out more sophisticated asset dashboards (such as furnaces).

User Dashboard

One of the things that the manager needed from the software was the ability to monitor and search employees.

We created an employee dashboard that allowed the manager to track simple information such as certifications, job title, and other relevant information.

We created different user levels, so that managers can see all dashboards as admins and other users can only see information relevant to their work.

Final Prototype

Asset Tracking / Monitoring:

-

General asset tracking & location - Ability to track location of all assets per site

-

Monitor lone worker - Track lone worker's whereabouts at anytime

-

Pad perimeter monitoring - Geofencing

Asset Information:

-

Asset inspections - Create and dill out custom inspections

-

Equipment information - Specifications, warranties, inspection documents, training videos

-

Live file mark ups - Ability to mark up and edit files live on the pad site

Floor Plan & Site Blueprints:

-

Locational based interface - Blueprint & assets automatically open when iPad enters geofence

-

Sharepoint sync - Customized file storage and sharing for company wide information

Marc

Head of Maintenance

Manages the maintenance team and oversees the purchasing for repairs and new equipment. His main goal is to reduce the workload of his employees on redundant tasks.

Sarah

Natural Gas Driver

Transports natural gas from the pad site to the production facilities. Runs into issues when employees are on the pad site when they aren't supposed to be due to gas emissions.

John

Corporate

Sits on the board and approves corporate spending. His main goal is to be able to save money and time for his company.